THE FLEXIBLE CONNECTION

Flexible hoses and fittings for the refrigeration industry

REFFLEX® is a product of The Netherlands and is applied by contractors and OEM customers all over the world. REFFLEX® is suitable for almost all non-corrosive refrigerants including natural gases.

- -40°C/115°C

- EN1736 Class 1

- ISO9223 ≥ C3

- UL Certified

The REFFLEX® fabricated portfolio

Why REFFLEX®?

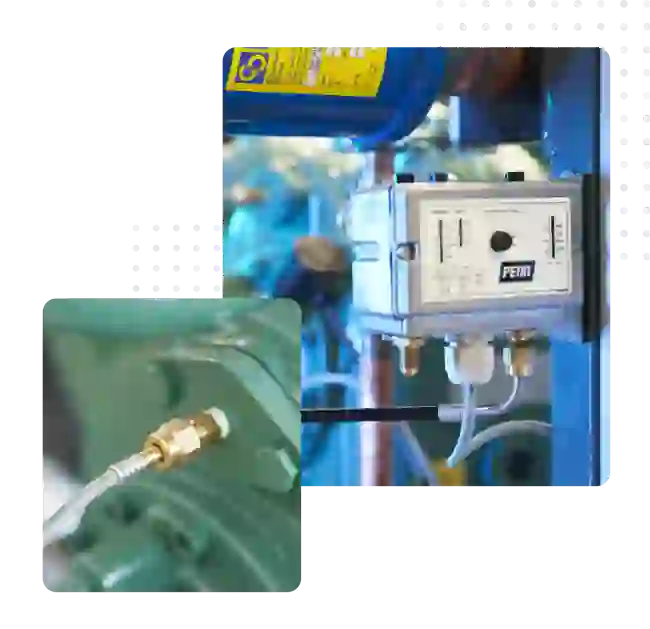

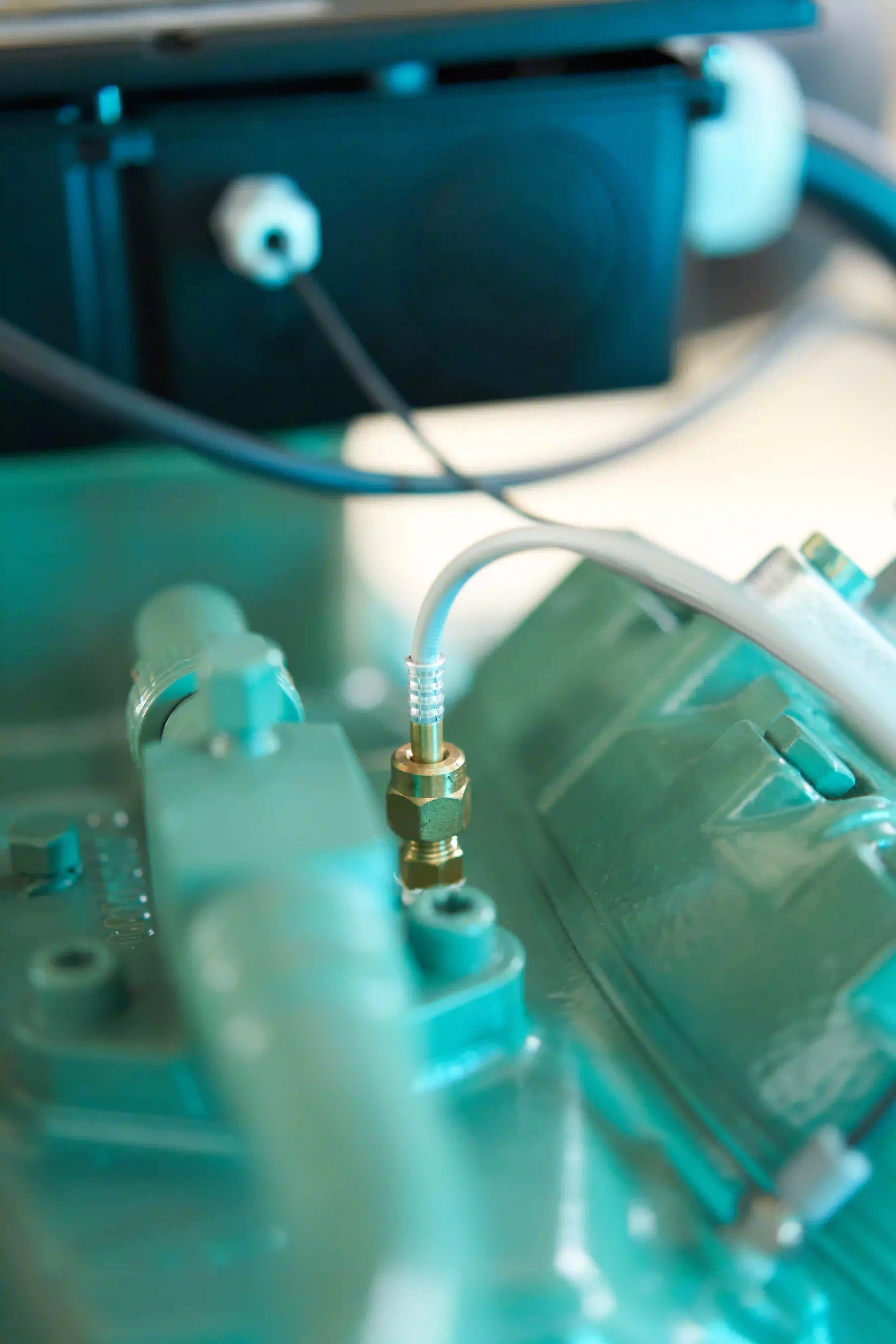

Refrigeration systems are subject to mechanical vibrations. These are caused by compressors, driving motors and gas pulsations, and are being transferred to equipment and pipe work. Small bore copper lines in the first place, as these are used for connecting auxiliary equipment such as pressure switches, are very vulnerable and taking up the vibrations, may grow brittle and the result could be a broken tube.

REFFLEX® is an extremely strong material and yet has a great vibration eliminating performance, vibrations do not come through! Apart from that, because of the simple way of making your own flexible connection, along with the wide range of special fittings, REFFLEX® is not only safe, it is cost reducing as well.

REFFLEX® is a product of The Netherlands and is applied by contractors and OEM customers all over the world. REFFLEX® is suitable for almost all non-corrosive refrigerants including natural gasses.

REFFLEX® products are tested and comply with EN1736 (permeability Class 1), ISO9223 (minimum class C3) and are UL recognised.

What to use for?

REFFLEX® simplifies the connection of:

- Pressure switches

- Pressure transducers

- Manometers

- Water flow controls

- Fan speed controls

- Oil seperators and level regulators (DN-5.0)

REFFLEX® offers the only acceptable connecting system for safety pressure switches, and is the exclusive system for connecting all sorts of oil return equipment.

Certified Products

Our tubes and fittings have been tested and comply with EN1736 and ISO9223

High temperature and pressure

Suitable for temperatures between -40°C and 115°C in combination with a max.working pressure of 80 bar

Fast delivery

We have large stock to keep lead times competitive, both for standard products and fabricated hoses.

Polyamide capillary hose

REFFLEX® is the most sophisticated system of polyamide capillary tubing, having excellent mechanical and thermal properties combined with a very high flexibility.

It is suitable for all non-corrosive refrigerants including natural gases such as CO2 and propane and the relevant special oils such as ester- an PAG.

REFFLEX® hose has the following excellent properties:

- highly flexible, bending at extreme short radius

- absorbing all possible multi directional vibrations

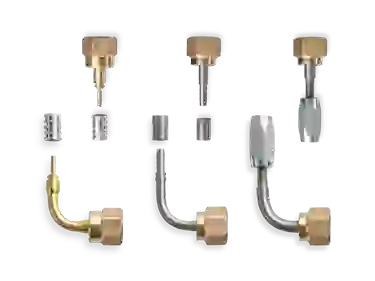

Various fittings

REFFLEX® offers a full range of straight-, angle - and T-connectors. The flared nuts for both DN-2.0 and DN-5.0 fittings are made of hot-forged brass, as is the best option for the refrigeration industry.

Both straight and angle connectors have the swivel nut sliding backwards far enough to position a copper gasket whenever required.

Access valve depressors are available with all 1/4" flare fittings.

Technical specifications

Dutch production sold in 35 countries

REFFLEX® is a high quality product of The Netherlands and is applied by contractors and OEM customers.

Our products are sold in over 35 countries worldwide through a fine network of distributors. Please contact us for a dealer near you.